Welding diecast metal can seem daunting, but with the right knowledge and techniques, you can achieve professional-quality results. This comprehensive guide will walk you through every step of the process, from understanding the material to mastering welding techniques and ensuring a safe working environment. Whether you’re a seasoned welder or a complete beginner, this guide will provide you with the information you need to confidently tackle diecast metal welding projects.

What is Diecast Metal

Diecast metal is created by injecting molten metal under high pressure into a mold. This process is used to produce complex shapes with high precision. Common diecast metals include aluminum, zinc, magnesium, and alloys thereof. These metals are known for their strength, lightweight properties, and ability to be formed into intricate designs, making them ideal for a wide range of applications, from automotive parts and electronics housings to toys and household appliances. Understanding the composition and properties of the specific diecast metal you are working with is crucial for successful welding.

Why Welding Diecast Metal is Challenging

Welding diecast metal presents unique challenges. The high silicon content, common in many diecast alloys, can lead to porosity and cracking in the weld. Additionally, the presence of trapped gases during the diecasting process can exacerbate these issues. The thin wall thickness of many diecast parts also requires careful control of heat input to avoid melting through the material. The welding process itself can introduce stresses that can lead to distortion or even failure if not managed correctly. Furthermore, the surface of diecast parts is often contaminated with oils and other residues, which must be meticulously cleaned before welding.

Common Problems When Welding Diecast Metal

Several problems can arise during diecast metal welding. Porosity, caused by gas entrapment in the weld, results in weak and unsightly welds. Cracking, another common issue, often occurs due to the high silicon content and rapid cooling rates. This can compromise the structural integrity of the part. Distortion, caused by uneven heating and cooling, can alter the dimensions and shape of the part. These issues underscore the importance of proper preparation, equipment selection, and technique when working with diecast metals.

Preparing for Diecast Metal Welding

Proper preparation is key to successful diecast metal welding. Begin by thoroughly cleaning the parts to remove any contaminants, such as oil, grease, paint, and oxidation. Use a degreaser, followed by a wire brush or abrasive pad, to ensure a clean surface. Next, if possible, preheat the parts to reduce thermal shock and improve weldability. The preheating temperature will depend on the specific alloy, but generally, temperatures between 200°F and 400°F (93°C and 204°C) are suitable. Finally, carefully align the parts to be welded, ensuring proper fit-up before starting the welding process. This will help minimize distortion and ensure a strong, accurate weld.

Selecting the Right Welding Equipment

The choice of welding equipment depends on the specific diecast metal and the desired outcome. TIG (Tungsten Inert Gas) welding is often preferred for its precision and control, allowing for minimal heat input. MIG (Metal Inert Gas) welding can also be used, especially for thicker sections, but requires careful adjustment of parameters. Ensure your equipment is suitable for the type of metal you are welding and that you have the necessary safety gear, including a welding helmet, gloves, and appropriate clothing. Select a welding machine capable of precise amperage control, especially when working with thin-walled diecast parts. Make sure the machine has the appropriate shielding gas for the type of welding, typically argon for aluminum and other non-ferrous metals.

Choosing the Right Filler Metal

Selecting the correct filler metal is critical for a strong and durable weld. The filler metal must be compatible with the base metal. For aluminum diecast alloys, use an aluminum filler rod or wire. Look for filler metals specifically designed for welding diecast aluminum alloys. Common choices include silicon-aluminum filler metals, which provide good weldability and strength. For zinc diecast, a zinc-based filler metal is recommended. Always consult a filler metal selection chart or the manufacturer’s recommendations to ensure compatibility and optimal weld performance. The filler metal should have a similar melting point and expansion coefficient as the base metal to minimize stress and cracking.

Welding Techniques for Diecast Metal

Employing proper welding techniques is crucial for success. Maintain a consistent travel speed and angle to ensure a uniform weld bead. Control the heat input to minimize distortion and prevent burn-through. Use a pulsed welding technique, when possible, to reduce heat input and control the weld pool. Pay attention to the weld pool and look for signs of porosity or cracking. Adjust the welding parameters, such as amperage, voltage, and travel speed, to optimize the weld quality. Proper technique involves maintaining a consistent arc length and making sure the filler metal melts and fuses with the base metal, creating a strong and seamless bond.

TIG Welding Diecast Metal

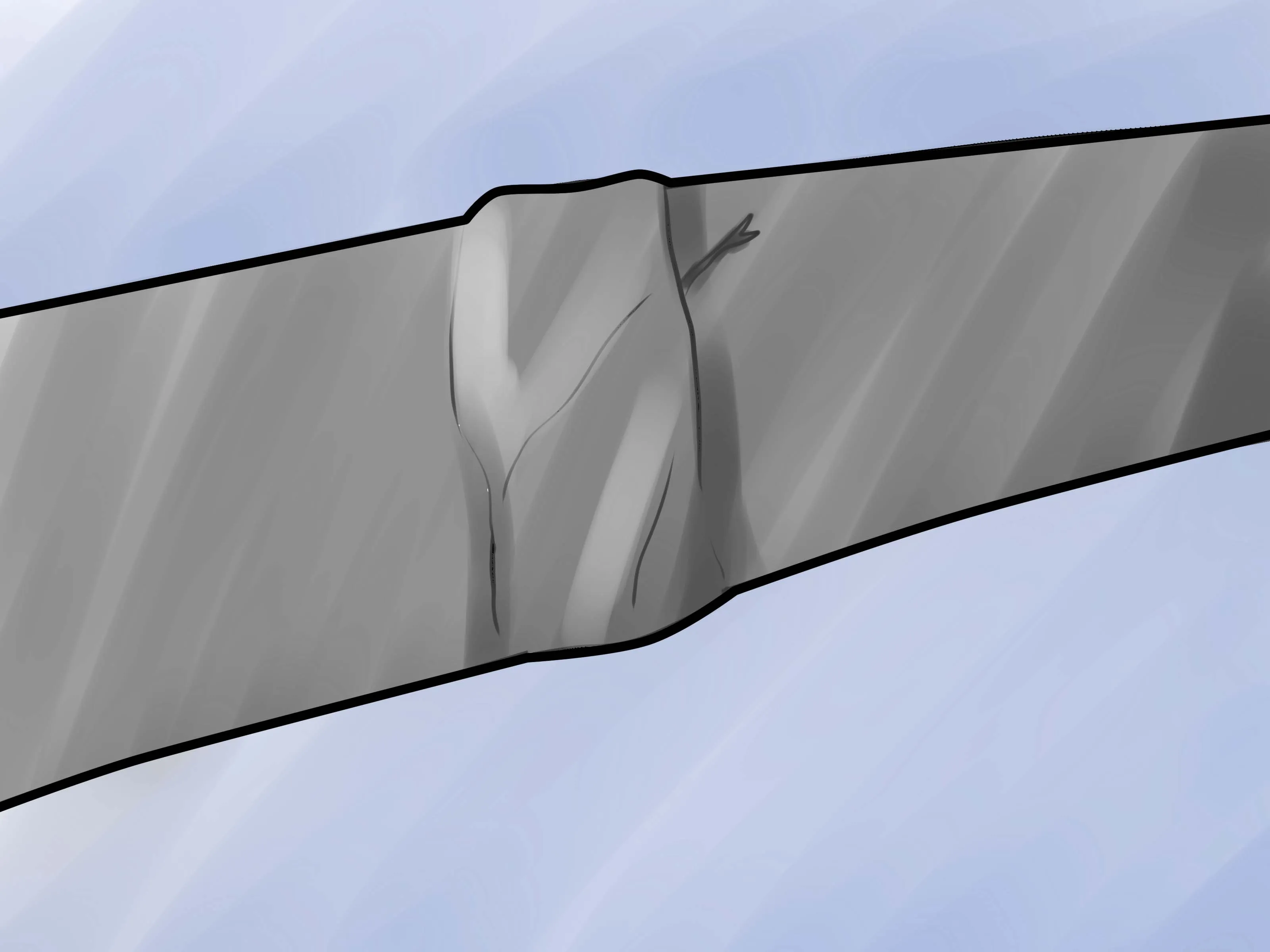

TIG welding is often the preferred method for diecast metal due to its precision and control. Use a sharp tungsten electrode, and select the appropriate shielding gas, usually pure argon. Set the amperage based on the thickness of the material and the desired weld penetration. Start with a low amperage setting and gradually increase it until the weld pool forms. Use a walking-the-cup technique or a steady hand to control the torch movement. Feed the filler metal into the weld pool smoothly and consistently. Avoid excessive heat input to prevent burn-through or distortion. TIG welding allows for precise control, which is essential for delicate diecast parts. See image: tig-welding-diecast.webp

MIG Welding Diecast Metal

MIG welding can be used for diecast metal, particularly on thicker sections or for faster welding speeds. Use the correct wire feed speed and voltage settings for the material and thickness. Ensure the shielding gas flow rate is appropriate to protect the weld from atmospheric contamination. Maintain a short stick-out distance (the distance between the welding wire and the nozzle). Use a push or drag welding technique, depending on the desired weld appearance and penetration. Adjust the wire feed speed and voltage to achieve a stable arc and a good weld bead profile. MIG welding often requires more practice than TIG welding, but it can be a faster and more efficient process for certain applications. See image: mig-welding-diecast.webp

Post-Welding Processes for Diecast Metal

After welding, several post-welding processes can improve the appearance, strength, and durability of the welded joint. Allow the welded part to cool slowly to minimize stress and prevent cracking. Remove any weld slag or spatter using a wire brush or other suitable tools. Consider heat treating the welded part to relieve stresses and improve its mechanical properties. This is especially important for critical applications. If necessary, grind or machine the weld to achieve a smooth and flush finish. The appropriate post-weld treatment depends on the specific alloy and the application requirements.

Cleaning the Welded Area

Cleaning the welded area is a vital step in ensuring the longevity and performance of your weld. The weld area should be cleaned thoroughly to remove any remaining slag, oxidation, or discoloration. This can be done by using a wire brush, abrasive pad, or a dedicated weld cleaner. If any discoloration remains, such as heat-affected zones, those can be removed using a stainless steel brush or other specialized tools. A clean weld area ensures the weld’s appearance and resistance to corrosion. See image: cleaning-welded-area.webp

Inspecting the Welded Area

Inspecting the weld is crucial for verifying its quality and integrity. Visually inspect the weld for any cracks, porosity, or lack of fusion. Ensure the weld bead has a consistent profile and that there are no undercuts. If necessary, use a magnifying glass to examine the weld more closely. For critical applications, consider non-destructive testing methods such as dye penetrant testing or X-ray inspection to detect subsurface defects. A thorough inspection helps to identify and correct any problems before the part is put into service. By making sure the welding is properly carried out, the risk of failure is significantly reduced, increasing the product’s durability. See image: inspection-welded-area.webp

Common Mistakes to Avoid When Welding Diecast Metal

Several common mistakes can compromise the quality of diecast metal welds. Overheating the material is a frequent issue, leading to burn-through, distortion, and weakened welds. Insufficient cleaning and preparation can result in porosity and contamination. Using the wrong filler metal or welding parameters will also cause problems. Another common mistake is rushing the process and not allowing adequate time for cooling. Insufficient penetration, which results in a weak joint, is also a significant mistake. Always take your time, use the right equipment, follow the guidelines, and avoid these common pitfalls to achieve successful diecast metal welds.

Safety Precautions for Welding Diecast Metal

Welding involves significant safety risks, so taking proper precautions is essential. Always wear a welding helmet with the appropriate shade lens to protect your eyes from harmful UV and infrared radiation. Wear gloves to protect your hands from heat, sparks, and potential electrical shock. Wear fire-resistant clothing, including a welding jacket or apron, to protect your skin from burns. Work in a well-ventilated area to avoid inhaling fumes, or use a respirator if necessary. Remove any flammable materials from the welding area. Make sure the work area is clear of any obstructions to prevent accidents. Follow all safety guidelines to ensure a safe and productive welding experience. See image: diecast-welding-safety.webp

By following these guidelines, you’ll be well-equipped to weld diecast metal with confidence and achieve professional-quality results. Remember to prioritize safety, practice your technique, and always consult the manufacturer’s recommendations for your specific materials and equipment.