What is Diecast?

Diecast is a manufacturing process that involves injecting molten metal, typically zinc, aluminum, or magnesium alloys, into molds to create intricate and detailed parts. This technique is widely used in various industries, from automotive and aerospace to consumer goods and toys. Diecast parts are known for their precision, strength, and ability to reproduce complex shapes. The process allows for high production volumes while maintaining tight tolerances, making it a cost-effective solution for mass production. Diecast components are often used in applications where durability and intricate designs are essential, making it a versatile and popular choice for manufacturers around the world.

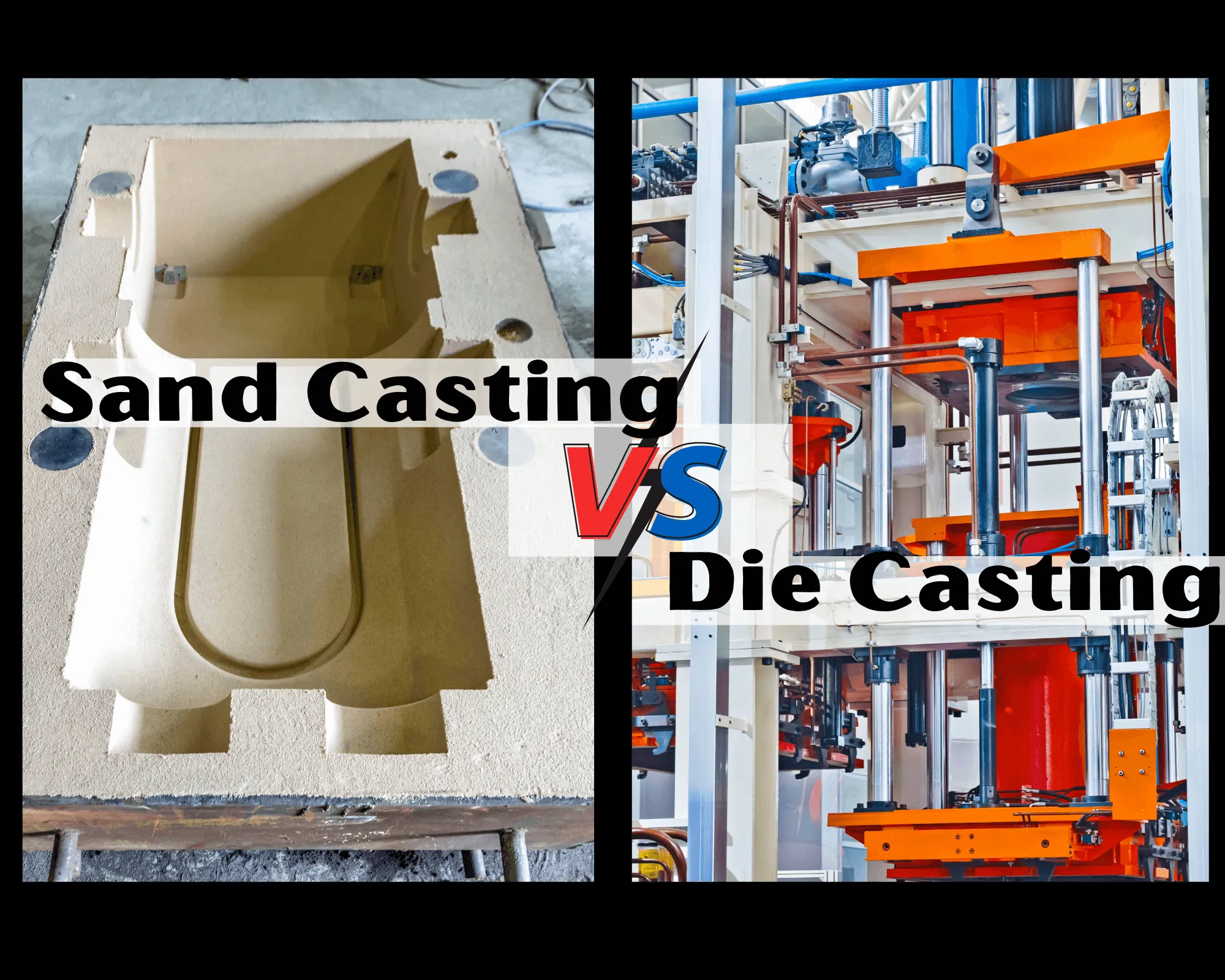

The Manufacturing Process of Diecast

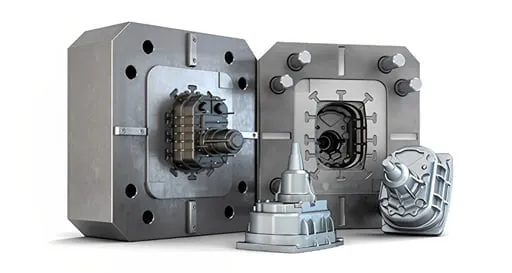

The diecast manufacturing process is a sophisticated operation that begins with the creation of a mold, often made from steel. This mold, or die, is designed to precisely match the desired shape of the component. Molten metal is then injected into the die under high pressure, ensuring that all details and intricate features are captured. Once the metal cools and solidifies, the die is opened, and the finished part is ejected. The process is highly automated, allowing for rapid production rates. After ejection, the parts often undergo trimming, finishing, and surface treatments to meet specific requirements. This process is optimized for precision, speed, and repeatability, making diecast a favored method for producing large quantities of complex parts with tight tolerances.

Advantages of Diecast

Diecast offers several advantages over other manufacturing processes. The process allows for the creation of parts with high dimensional accuracy and intricate designs. Diecast components can be produced at high speeds, resulting in cost-effective mass production. The ability to use a variety of alloys also offers flexibility in terms of material properties. Diecast parts typically exhibit excellent surface finishes, reducing the need for additional finishing processes. The strength-to-weight ratio of diecast components is also favorable, making them suitable for applications where weight is a concern. The process is environmentally friendly, as it generates minimal waste materials, and all the scrap material can be recycled, leading to a reduction in material costs and environmental impact.

Durability and Strength

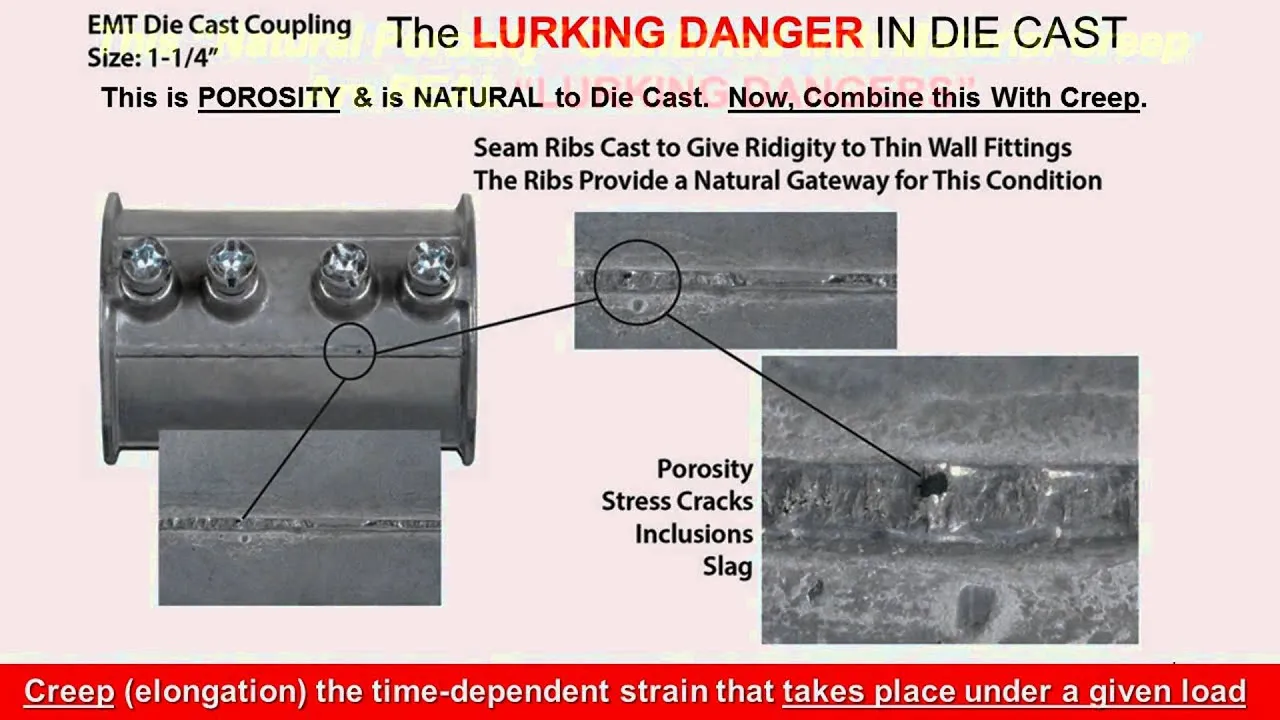

Diecast components are known for their strength and durability. The high-pressure injection process results in a dense and solid structure, capable of withstanding significant stress and impact. The choice of alloys plays a significant role in determining the mechanical properties of diecast parts. Zinc alloys offer good tensile strength and impact resistance, while aluminum alloys provide a higher strength-to-weight ratio. The durability of diecast components makes them ideal for applications where parts are subject to harsh conditions or frequent use. They are therefore suitable for use in vehicles, machinery, and other equipment. Properly designed and manufactured diecast parts can last for many years, even under demanding conditions.

Fine Details and Accuracy

One of the major advantages of diecast is its ability to produce parts with fine details and high dimensional accuracy. The high-pressure injection process enables the creation of intricate features and complex shapes that would be difficult or impossible to achieve using other manufacturing methods. This precision is crucial in applications such as automotive parts and electronics, where tight tolerances are necessary to ensure proper functionality. The ability to replicate fine details also allows designers to create aesthetically pleasing and functional products. Diecast tooling can be very complex, and it requires skilled engineers and advanced equipment to produce high-quality parts with precise details.

Cost Effectiveness

Diecast is a cost-effective manufacturing process, especially for high-volume production runs. The initial investment in tooling can be significant, but the rapid production rates and minimal material waste make it economical in the long run. The high-pressure injection process allows for quick cycle times, reducing the manufacturing cost per part. Furthermore, diecast parts often require minimal finishing processes, which can reduce overall production costs. The ability to use a wide range of alloys, also allows manufacturers to choose the most cost-effective material for each application. Cost-effectiveness is a critical factor that makes diecast a preferred option in the automotive, consumer goods, and other industries.

What is Steel?

Steel is an alloy primarily composed of iron and carbon, with carbon content typically ranging from 0.002% to 2.1%. It is one of the most widely used materials in the world due to its versatility, strength, and cost-effectiveness. Steel can be produced in a variety of grades and compositions, each with unique properties tailored to specific applications. Different alloying elements, such as manganese, chromium, and nickel, can be added to enhance steel’s mechanical properties, such as hardness, corrosion resistance, and ductility. The versatility of steel makes it suitable for numerous industries, including construction, automotive, and manufacturing. From bridges and buildings to cars and appliances, steel plays a vital role in modern society.

The Manufacturing Process of Steel

Steel manufacturing involves several steps, beginning with the extraction of iron ore. The ore is then processed to remove impurities and create iron. This iron is then combined with carbon, and other alloying elements are added to create the desired steel grade. The steel is then shaped using various methods, such as rolling, forging, or casting. The process can be adjusted to produce a wide range of steel products, from structural beams to thin sheets. Different heat treatments can also be applied to alter the steel’s mechanical properties, such as hardening, annealing, and tempering. Modern steel mills employ advanced technologies to ensure consistent quality, efficiency, and environmental sustainability.

Advantages of Steel

Steel offers numerous advantages, including high strength and durability, making it suitable for structural applications. Its high strength-to-weight ratio is beneficial in construction, automotive, and aerospace applications. Steel is also a relatively cost-effective material. The ability to recycle steel reduces environmental impact and provides a sustainable material source. Steel’s versatility enables it to be formed into a wide range of shapes and sizes. Steel can also be customized through various alloying elements and heat treatments, which can enhance its mechanical properties. The material’s widespread availability and well-established manufacturing processes also make it easy to source and process.

Durability and Strength

Steel is renowned for its exceptional strength and durability. The high tensile strength of steel allows it to withstand significant loads and stresses. Steel structures are designed to resist deformation and failure, even under extreme conditions. The material’s durability makes it an excellent choice for applications that require longevity and resistance to wear and tear. Steel is also resistant to impacts and can absorb substantial amounts of energy. The durability of steel is a critical factor in infrastructure projects, automotive manufacturing, and many other industries. The material can withstand harsh environments and provides excellent performance over many years.

Cost Effectiveness

Steel is a cost-effective material in many applications. Its widespread availability and efficient manufacturing processes contribute to its relatively low cost. The ability to recycle steel and use it in new products reduces raw material costs and environmental impact. Steel’s high strength-to-weight ratio allows for efficient designs and reduces the amount of material needed. Furthermore, the use of steel can decrease construction time and labor costs. Steel is often a more economical choice than alternative materials. The combination of strength, durability, and affordability makes steel an attractive material for a variety of industries and projects.

Versatility

Steel’s versatility stems from its ability to be tailored to meet specific needs. Different grades of steel offer unique properties, ranging from high strength to enhanced corrosion resistance. Steel can be formed into various shapes, including beams, plates, and sheets, through a variety of manufacturing processes. It can be used in an extensive range of applications, from construction and automotive to consumer goods and manufacturing. Steel can also be combined with other materials to create composite structures that offer enhanced performance. The adaptability of steel allows designers and engineers to create innovative solutions that meet evolving industry requirements. The material can also be processed into different finishes.

Diecast vs Steel Materials, Properties Comparison

Strength and Weight

The strength and weight of diecast versus steel depend on the specific alloys and grades used. Steel generally offers higher tensile strength compared to diecast alloys, making it suitable for applications requiring load-bearing capacity. However, diecast alloys, particularly aluminum, offer a better strength-to-weight ratio, leading to lighter components. This is crucial in automotive and aerospace, where reducing weight can improve fuel efficiency and performance. The selection of the right material depends on the application and the desired balance between strength and weight. If a lightweight, strong component is needed, an aluminum alloy diecast may be suitable, whereas steel will be needed for extreme conditions.

Cost and Production

The cost and production considerations differ significantly between diecast and steel. Diecast is generally cost-effective for high-volume production due to its rapid cycle times and minimal waste. The initial investment in tooling for diecast can be high. Steel, on the other hand, often has lower initial tooling costs, especially for simple shapes. The production process for steel can be more labor-intensive, especially for intricate shapes, which could lead to higher production costs. The choice between the materials depends on the production volume, complexity of the part, and required material properties. Low-volume or large parts are often better suited for steel, while mass production is ideal for diecast.

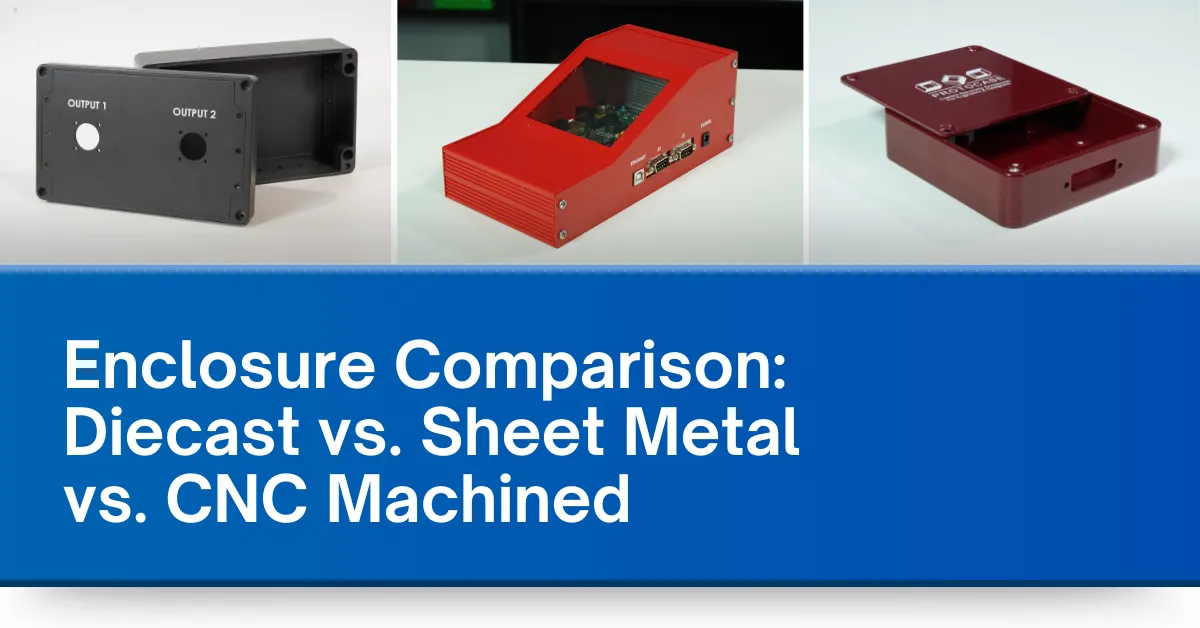

Appearance and Details

Diecast parts offer superior capabilities in terms of appearance and detail. The high-pressure injection process allows for the creation of intricate designs, fine surface finishes, and complex geometries. Steel can also be used to create aesthetically pleasing parts, but it often requires additional finishing processes to achieve the same level of detail. Diecast can often achieve very smooth surfaces directly from the mold, reducing the need for secondary finishing operations. The ability to reproduce fine details is particularly important in consumer products and decorative applications. The final appearance of the part can be critical for its marketability and usability.

Maintenance and Longevity

Both diecast and steel parts can provide excellent longevity and require minimal maintenance, depending on the application and environmental conditions. The durability of each material is a key factor. The longevity of steel can be affected by corrosion, but this can be mitigated through the use of protective coatings and alloys. Diecast components, particularly those made of aluminum alloys, can be prone to corrosion, but they can also be protected with coatings. The maintenance requirements of both materials depend on the specific application and the level of exposure to environmental factors. Routine inspections, cleaning, and proper maintenance can extend the lifespan of both diecast and steel parts.

Applications of Diecast and Steel

Diecast Applications

Diecast is used in various applications, including automotive components, such as engine parts, transmission housings, and body panels. It is also used in consumer electronics, including housings for smartphones, laptops, and other devices. Diecast is often used for toys, model cars, and other collectibles. In the aerospace industry, diecast components are found in aircraft engines and other critical parts. Diecast’s ability to create complex and precise shapes makes it ideal for these applications, where performance, detail, and cost-effectiveness are essential. The wide range of applications demonstrates the versatility and usefulness of the diecast process.

Steel Applications

Steel is used extensively in construction, forming the backbone of buildings, bridges, and infrastructure projects. The automotive industry uses steel for vehicle frames, body panels, and other structural components. Steel is a key material in manufacturing, used for machinery, tools, and equipment. It is also used in the transportation industry, including railways, ships, and aircraft. In addition, steel is used in appliances, consumer goods, and packaging. Steel’s versatility and strength make it an essential material across many sectors. The range of applications demonstrates its importance.

Which is Better for You?

The choice between diecast and steel depends on the specific requirements of your project or application. Consider the desired strength, weight, cost, and level of detail. If you need high-volume production of intricate parts with a focus on weight savings, diecast may be the better choice. If strength, durability, and cost-effectiveness are crucial for larger components, steel might be the better option. It’s important to consider the environmental impact, as both materials can be recycled. Analyzing the specific needs of your project, and consulting with material experts, is a good idea. Both diecast and steel are valuable materials, each with unique properties.

Factors to Consider When Choosing

When choosing between diecast and steel, several factors should be considered. The required mechanical properties, such as strength, durability, and weight, are essential. Production volume is also a key consideration, as diecast is more cost-effective for mass production. The complexity of the design and the level of detail needed. Another factor is the environmental impact of the material. The cost of the material and the manufacturing process. Long-term maintenance and the operating environment of the part. Consulting with experienced engineers and designers can help you choose the most suitable material.

Conclusion

Both diecast and steel offer unique advantages, making them important materials in manufacturing and engineering. Diecast excels in creating intricate, detailed parts with high production volumes, while steel provides exceptional strength and versatility for a wide range of applications. The choice between these materials depends on the specific needs of your project. Considering factors such as strength, weight, cost, and design complexity will lead to the best decision. Both materials have a significant impact on modern technologies and are essential for innovation and progress.