1 64 Alloy Wheels What Are They?

In the miniature world of 1 64 scale diecast cars, the smallest details can make the biggest difference. One of the most impactful upgrades you can make to your collection is adding 1 64 alloy wheels. These aren’t just mere replacements; they’re a gateway to a whole new level of realism and customization. Unlike the stock plastic wheels that often come with these models, alloy wheels offer a level of detail and durability that drastically improves the overall aesthetic. They replicate the look and feel of real-world wheels, made from materials that provide both strength and intricate design possibilities. Whether you’re a seasoned collector or new to the hobby, understanding the significance of 1 64 alloy wheels is the first step in elevating your diecast car game. These wheels provide a fantastic base to create a truly unique collection of cars.

Why Use 1 64 Alloy Wheels?

The benefits of upgrading to 1 64 alloy wheels extend beyond mere aesthetics. They offer a range of advantages that can significantly enhance your diecast car experience. Primarily, alloy wheels are designed to improve both the look and performance of your cars. The enhanced details, often mimicking real-world wheel designs, instantly make your models more realistic and visually appealing. This attention to detail is crucial for collectors who appreciate accuracy and realism. In terms of performance, alloy wheels can also improve the rolling characteristics of your diecast cars. Heavier, more robust alloy wheels provide better stability and smoother movement on surfaces. Furthermore, alloy wheels give you a solid base for customization. They are much easier to paint and modify. This gives you a great deal of creative freedom to design cars to your exact liking.

Enhance the Look of Your Diecast Car

The primary appeal of 1 64 alloy wheels lies in their ability to transform the appearance of your diecast cars. The superior detailing compared to stock wheels is immediately noticeable. Alloy wheels come in a variety of styles, from classic designs to modern, performance-oriented looks. This variety allows you to customize your cars to reflect specific real-world models or create entirely unique builds. The addition of alloy wheels can significantly increase the value and visual appeal of your models. Consider the difference between a standard plastic wheel and a meticulously crafted alloy wheel – the latter adds a touch of class and authenticity that elevates the entire display. This visual upgrade is a key reason why many collectors choose to invest in alloy wheels, transforming their collection into a more premium display.

Improve Diecast Car Performance

Beyond aesthetics, 1 64 alloy wheels can improve the performance of your diecast cars. Heavier alloy wheels offer increased stability, especially on surfaces that are not perfectly level. This enhanced stability can lead to smoother rolling and reduced wobble, making your cars look and perform better. Many alloy wheels are designed with superior bearings or smoother rolling surfaces, directly improving how well the car moves. While the performance gains might seem modest at this scale, they contribute to a more enjoyable experience, particularly if you enjoy racing or simply displaying your cars. The improved rolling performance provides a much better feel, making the models more fun to handle and appreciate. Ultimately, the enhanced performance, combined with improved aesthetics, makes alloy wheels a worthwhile upgrade for any enthusiast.

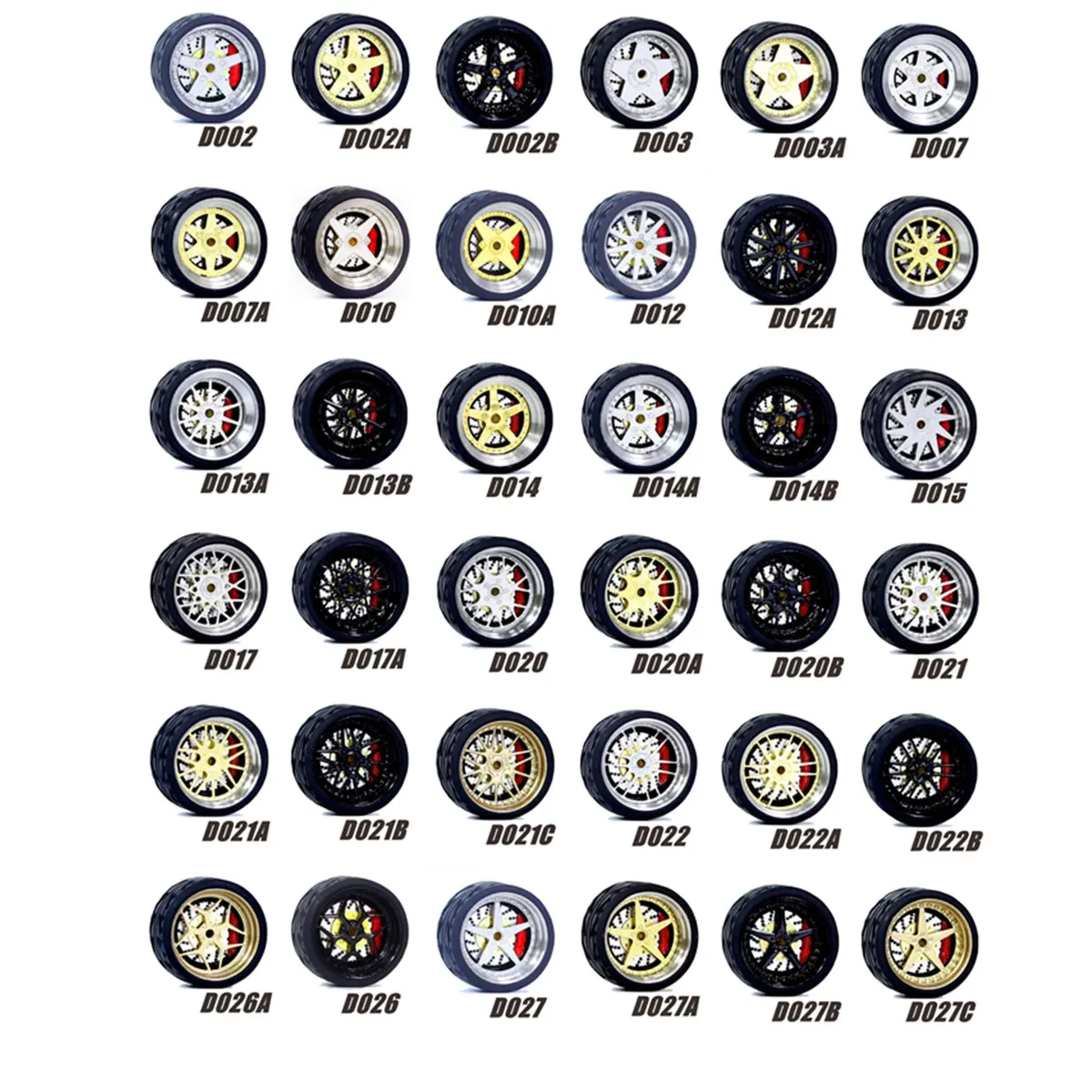

1 64 Alloy Wheels Types and Styles

The world of 1 64 alloy wheels is vast and varied, offering a plethora of options to suit every taste and diecast car model. The styles available mimic real-world wheel designs, from classic five-spoke wheels to intricate multi-spoke designs, and even modern aftermarket styles. This diversity allows you to personalize your diecast cars to an extraordinary degree. Material choices also play a significant role. The alloy material itself contributes to the durability and the overall look of the wheels. High-quality alloys offer the perfect blend of strength, weight, and visual appeal, ensuring your wheels can withstand the test of time. Selecting wheels that are the right style and material is crucial to achieving your desired look, and the range of options available provides ample opportunity for creativity and precision in your customization.

Different Materials for 1 64 Alloy Wheels

The choice of materials for 1 64 alloy wheels is diverse, with each option offering unique characteristics in terms of appearance, durability, and performance. Aluminum alloys are a popular choice due to their balance of strength and lightweight properties, as well as their ability to hold intricate detailing. They are also easily customizable through painting and finishing. Another material used is die-cast zinc alloy, a more affordable option often found in mass-produced wheels. This material provides decent durability and can be a good starting point. The material you choose will greatly affect the look of your wheels. By carefully considering the various material options, you can select wheels that best fit your style preferences, budget, and the specific needs of your diecast car project.

Wheel Size and Fitment

Correct wheel size and fitment are essential considerations when upgrading to 1 64 alloy wheels. The size must be proportionate to your diecast car model to maintain a realistic look. It’s also important to ensure the wheels fit within the wheel wells without rubbing or interfering with the car’s suspension or body. Carefully measuring the existing wheel diameter and width is a necessary step. Consider the offset, which impacts how far the wheel sits in or out of the wheel well. Different wheel styles and materials can also affect the weight and rolling characteristics of your car, so matching the fitment to the type of car you have in mind. Pay attention to the axle size as well. Making informed decisions regarding wheel size and fitment will ensure the wheels not only look great but also enhance your diecast car’s performance and overall appeal.

Choosing the Right 1 64 Alloy Wheels

Selecting the right 1 64 alloy wheels is a process that combines your personal preferences, the style of your diecast car, and your customization goals. Start by assessing the look you want to achieve. Are you going for a classic, vintage feel, or a modern, sporty aesthetic? Browse through various wheel styles to find those that resonate with your vision. Consider the overall theme of your collection. Match your wheel choices to the era, make, and model of the diecast cars you’re customizing. Also, consider the quality of the wheels, considering the materials used and build quality. Higher-quality wheels often offer better detail and durability. Choosing alloy wheels allows you to showcase the full potential of your diecast cars.

Consider Your Diecast Car Model

The specific model of your diecast car plays a significant role in the wheel selection process. Different cars have different design themes, so the alloy wheels you choose should complement these. A classic muscle car would look great with deep-dish wheels, while a modern sports car might look better with sleek, multi-spoke designs. Researching images of real-world cars can help you find wheel styles that match your diecast car model. Paying attention to the original wheel design can provide inspiration for what kind of upgrades will look the best. For example, you can also look for wheels that mimic the factory wheels of the original car if you want a more accurate display. Careful model consideration ensures that the new wheels enhance the car’s existing design, rather than clashing with it. This attention to detail will allow you to create a cohesive and visually appealing collection.

Consider Your Customization Goals

Your customization goals will ultimately guide your alloy wheel selection. If your goal is to replicate a specific real-world car, you’ll want to search for wheels that closely match the original design. If you are aiming for a unique, custom look, the range of possibilities widens significantly. Consider whether you want to keep the cars simple, or go for a themed approach. This involves selecting wheels that match the desired color scheme, style, or theme of your build. Decide how much effort you are willing to invest in the customization process. Will you be painting, modifying, or adding details to the wheels? Your goals will dictate the types of wheels you need and the extent of your modification. By clarifying your goals, you can narrow down your wheel choices and ensure a successful and satisfying customization experience.

1 64 Alloy Wheels Installation Guide

Installing 1 64 alloy wheels is a manageable task, often within reach of model car enthusiasts of all skill levels. The process involves a few key steps, from preparing your diecast car to mounting the new wheels. Precise preparation, careful execution, and attention to detail are critical to achieving the best results. Before beginning, gather all necessary tools, including a small screwdriver, pliers, and possibly a hobby knife. Having everything ready will help the process go smoothly. Also, ensure your workspace is clean, well-lit, and free of distractions. Following these steps will improve your installation experience and the final look of your customized diecast cars.

Preparing Your Diecast Car for New Wheels

Preparing your diecast car is the first step in the installation process. This includes removing the existing wheels. Most diecast cars have wheels that are either press-fit onto axles or held in place with small pins. Gently remove the existing wheels. Inspect the axles for any damage or wear and tear. If the axles are bent or damaged, consider replacing them with new ones to ensure smooth rolling. Next, clean any glue or debris from the wheel wells. Cleaning the wheel wells will create a clean surface for the new wheels, maximizing the aesthetics of the model. By taking the time to prepare your diecast car, you ensure a smooth installation process and lay the groundwork for a successful wheel upgrade.

Installing 1 64 Alloy Wheels

Once your car is prepared, the next step is installing the new 1 64 alloy wheels. Carefully align the new wheels with the axles. Press the wheels onto the axles. Make sure that the wheels rotate smoothly. If the wheels are too tight, gently widen the gap with a small tool or replace the axle. Be cautious, as excessive force can damage the wheels or the car. You can use a small amount of glue to keep the wheels securely in place. Once the wheels are installed, test their rolling performance on a flat surface. Check that the wheels spin freely and do not rub against the body or wheel wells. By following these steps, you can ensure that the new wheels are installed correctly and provide the desired aesthetic and performance improvements.

Maintaining Your 1 64 Alloy Wheels

Proper maintenance is key to keeping your 1 64 alloy wheels looking their best. Regular cleaning and care are crucial to preserving the finish and ensuring they continue to enhance your diecast car’s appearance. You must protect them from potential damage. By incorporating these maintenance practices into your routine, you will keep your wheels looking great for years to come.

Cleaning and Care Tips

Cleaning your 1 64 alloy wheels regularly helps to prevent the build-up of dust and grime, maintaining their luster. Use a soft brush and a mild soap solution to gently clean the wheels. Avoid using harsh chemicals or abrasive cleaners, as they can damage the finish. Use a microfiber cloth to dry the wheels, preventing water spots and keeping them looking their best. Inspect the wheels regularly for any signs of damage, such as scratches or fading, and address these issues promptly. By following these simple cleaning and care tips, you can keep your alloy wheels looking their best, ensuring they continue to enhance your diecast cars.

Protecting Your Alloy Wheels

Protecting your 1 64 alloy wheels from damage is an essential part of their upkeep. Store your diecast cars in a cool, dry place. Use protective display cases or cabinets to shield the wheels from dust and direct sunlight, which can cause fading. Handle the cars with care. Minimize the risk of scratches or damage by handling them gently. When displaying your cars, position them carefully to avoid accidental contact or drops. Consider applying a clear coat or sealant to the wheels for added protection against scratches and environmental elements. Protecting your alloy wheels ensures that they will continue to enhance the look of your diecast cars for years to come.

Conclusion

Upgrading to 1 64 alloy wheels is a fantastic way to customize and enhance your diecast car collection. They offer significant benefits, from improving aesthetics and performance to providing a solid base for further personalization. Choosing the right wheels involves considering your car’s model, customization goals, and wheel styles. Properly installing and maintaining alloy wheels ensures they continue to look their best. Whether you’re a seasoned collector or just starting, the addition of alloy wheels is a rewarding and impactful upgrade that elevates your diecast car experience. Enjoy the process of customizing and refining your diecast cars to create a truly unique and impressive collection!